Warp is rolling out warehouse robots to slash labor costs and boost efficiency.

The shipping tech startup, backed by Walmart, Gopuff, and HelloFresh, is automating workflows inside its warehouses using off-the-shelf robots with custom tweaks. It can’t automate trucking or delivery, so it’s focused on the warehouse floor.

The company started by fitting cameras into its Los Angeles test warehouse, creating a digital twin. That let Warp experiment heavily—starting with humanoid robots pushing pallet jacks (which flopped), then moving to simpler robot setups.

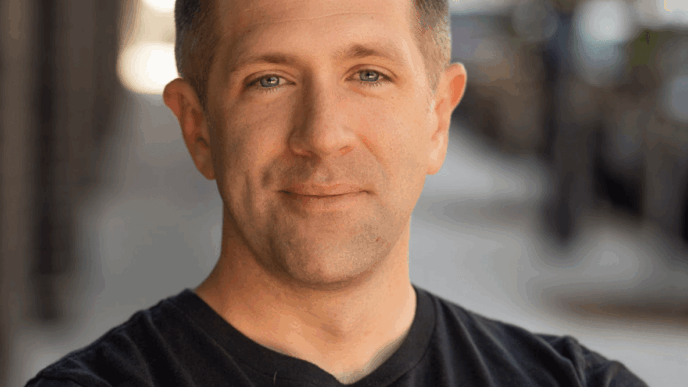

Warp co-founder and CEO Daniel Sokolovsky explained the approach:

“We effectively made a digital twin, or simulation environment for our LA facility,” Sokolovsky said. “[We] basically started just like throwing stuff at the wall. Honestly, a lot of it was, what happens if we do this? What happens if we do that? What happens if we do that other thing?”

The goal: use AI and robotics to handle unloading, storing, and reloading freight without adding headcount.

“We’ve taken really, really complicated logistics problems, divided them into a lot of easily digestible, system understood and system-fed components,” Sokolovsky said. “We are now using, whether it’s AI in the form of voice, text, email, phone calls or robotics, [to make sure] that we’re unloading, storing and reloading freight. We actually think that we can actually continue this on, and really get to our goals as quickly as possible, without hiring more people.”

Warp co-founder and CRO Troy Lester added that warehouse partners struggle with staffing, so robots could ease those pains and give those partners a competitive edge.

“They’re complaining to us about staffing issues all the time,” Lester said. “The labor that’s doing the work in these facilities, they’re not liking it either. So I think there is an opportunity to kind of empower those businesses to have these robotic kits that would not only help make our network better, but help make their business with other companies better as well.”

Warp just closed a $10 million Series A round led by Up.Partners and Blue Bear Capital to fuel this push.

The L.A. warehouse is fully autonomous now. Warp plans to deploy robots across its main hubs in Los Angeles, Chicago, New Jersey, Dallas, and Miami starting this year. The tech won’t be sold externally—Warp wants to keep this system exclusive for its logistics network advantage.

“Instead of going out and saying, hey, we’re just a robot company, AI company, and spend money on like this potential concept, it’s like, no, we’re actually a logistics company that has been really impacting and servicing our customers,” Sokolovsky said. “For the past few years now, we’ve developed an amazing system and an ecosystem that’s allowing us to deploy these kinds of automations.”

Warp is betting robots will be the next big move in streamlining supply chains from the inside out.